Meeting Minergie and SIA 180 standards

Classic blower door tests are usually carried out to verify the airtightness of building envelopes or apartments, particularly in the context of Minergie-P buildings. It is crucial to comply with the specified requirement value of the Minergie Association for Minergie-P buildings. The main objective is to limit uncontrolled heat loss due to pressure differences in the building envelope and at the same time to prevent odor transmission into apartments. It is important to note that airtightness limits are not only set by Minergie, but also by the SIA 180 standard - an aspect that is often overlooked.

Applications and implementation of blower door measurements

The following video illustrates how the installation and use of the blower door measuring equipment works:

A-value measurement: determining the air exchange rate of windows for precise analyses

Another variant of the blower door application is the a-value measurement. In this type of measurement, the air exchange rate of installed windows is determined so that it can then be compared with laboratory values.

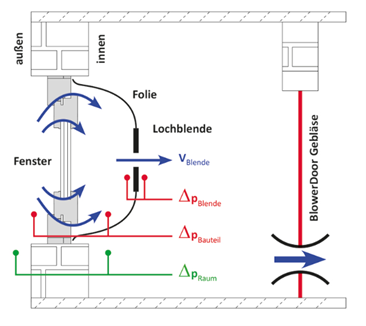

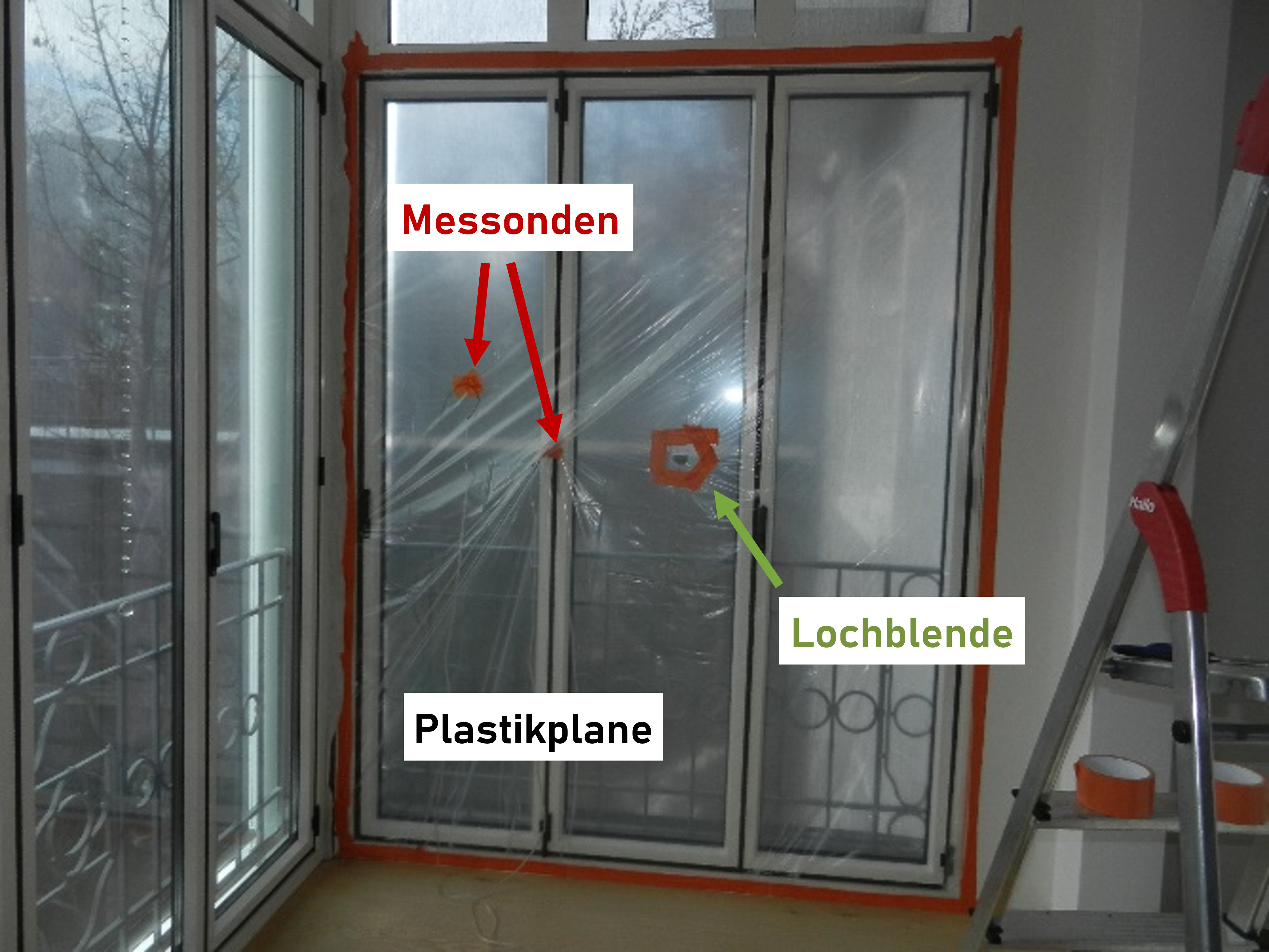

In an a-value measurement, a foil with a perforated screen is applied to the window to be tested. The fan is used to generate a pressure difference that is continued in the cavity between the window and the film - the film therefore slowly bulges inwards.

The volume flow that penetrates through the window joints is determined using a perforated screen with a defined opening and the pressure difference before and after the screen (Δp screen).

(Source: BlowerDoor GmbH)

In expert reports, a-value measurements are often used to determine whether windows are leaking or whether there is a problem with cold air leakage in the event of comfort problems. Although the a-value measurement was originally developed for in-situ measurements of windows, partial areas of facades or parts of buildings can also be tested and quantified for their airtightness.

Airtightness tests in building damage analyses: thinking beyond limit values

Compliance with specified requirements and limit values for the airtightness of building envelopes does not guarantee the absence of structural damage. For this reason, airtightness tests using flow test tubes or discone fog are used for building damage analyses and to ensure that the building is free of damage. The many years of expertise and know-how of a building physicist are required to assess the susceptibility to structural damage.

Procedure and objectives for leak detection

In contrast to blower door measurements, which result in an exact measured value for assessing the airtightness of the building envelope, leakage searches are used to find component-specific air leaks in the building envelope, in this case in the walls surrounding the room.

For this purpose, a negative pressure is created in the room to be examined using a fan - similar to blower door measurements.

In a first step, air flow test tubes are then used to search for air leaks along the critical points (component transitions, masking, pipe penetrations, etc.). Any leaks found are marked.

In a second step, the room is completely filled with a dense, long-lasting fog (similar to disco fog). Due to the overpressure in the room, the mist is forced through any air leaks and then reappears outside the room.

These two methods provide feedback on possible leaks. Air leaks can be detected with pinpoint accuracy using the flow test tubes. The fog method also reveals possible air leaks that are located in unexpected, inaccessible and hidden places or those that were overlooked with the air flow test tubes.

Supporting measures for leak detection in the event of structural damage

For further investigations into structural damage, the airtightness measurement method is often used in combination with thermal imaging cameras.

The differential image method is somewhat complicated to use for this purpose. We therefore like to use the simplified application described below:

In a first step, we take a photo with the infrared thermography camera of external building parts or connections, e.g. window connections, an area with mold growth or any other component to be inspected. We document the exact location and height of the camera. The building or the room in question is then placed in a defined negative pressure state (e.g. -50 Pa) for 15 minutes. We repeat the images with the infrared thermography camera after the said 15 minutes at the documented location with the same settings.

In the office, we can now place the two photos next to each other and compare the measured surface temperatures. This makes it quick and easy to see whether the area in question is cooling due to air leaks or whether a thermal bridge is causing structural damage.

Briefly summarized:

Blower door measurements are not only used to check the airtightness of the building envelope, but are also a powerful, efficient tool for investigating and detecting leaks and preventing structural damage.

/www.gundp.ch/file/2338/1_Blower_Door_Schematische_Darstellung.png)

/www.gundp.ch/file/2341/2_Blower_Door_Aufbau.png)

/www.gundp.ch/file/2340/3_Blower_Door_Nebelmaschine.png)

/www.gundp.ch/file/2339/4_Blower_Door_Leckagen.png)

/www.gundp.ch/file/1384/Haus_Meilen_Bauphysik_Beratung.png)

/www.gundp.ch/file/1672/Titelbild_Golatti_Quadratisch.jpg)

/www.gundp.ch/file/1684/fachanlass_label_quadrat.jpg)